Quality control is a vital aspect in any production unit, and it receives special attention.

Quality control testing is necessary to ensure that the client receives the particular product that they requested. We pay close attention to the quality testing of every granite slab produced by our unit. We use experienced and specialized inspectors with more outstanding expertise to communicate excellent quality to the clients. It does not come to an end but rather is a continuous activity.

Quality control testing includes stone toughness, durability, resistance to water, dampness, severe temperature fluctuations, and microorganisms. Packaging testing is included in post-production testing—the quality of Installation. A professional installer can make a low-quality granite counter appear friendly. A poor installation might ruin beautifully crafted countertops. It would help if you had competent and skilled installers to obtain superb granite counter work.

Advantages Of Quality Control

Cost savings in production

Production expenses are significantly decreased by conducting efficient inspections and control over production processes and activities. Quality control also prevents the manufacturing of substandard items and waste, lowering production costs significantly.

The most efficient use of resources

Quality control ensures that existing resources are used to their full potential, reducing waste and inefficiency of all kinds.

Cost savings on inspections

Quality control results in inspection efficiencies and significantly lowers inspection costs.

Employee morale is higher

An efficient quality control system is highly beneficial in raising employee morale and making them feel as though they are working in a company creating better and higher-quality products.

Employer-employee relations have improved

Quality control contributes to a better industrial environment by raising staff morale, ensuring amicable employer-employee interactions, resulting in greater understanding and intimacy between them.

Allows for price-fixing

The use of quality control procedures results in the production of consistent items of the same quality. This considerably simplifies the issue of price-fixing. The market gets dominated by single pricing for typical items.

Enhanced sales

Quality control promotes high-quality items, which is hugely beneficial in drawing more clients and growing sales. It is conducive to both maintaining current demand and developing new orders for the product. It has been correctly said that quality control is an excellent tool for expanding domestically and internationally.

Promotes quality awareness

The most significant benefit of implementing quality control is that it promotes and fosters quality consciousness among factory employees, which is highly beneficial in obtaining the target degree of quality in the product.

Consumer satisfaction

Consumers profit substantially from quality control since they receive higher-quality items. It provides them with satisfaction.

Enhanced compassion

Quality control increases the concern’s goodwill in people’s minds by providing higher-quality goods and meeting the demands of customers. A well-known company may readily raise funds from the market.

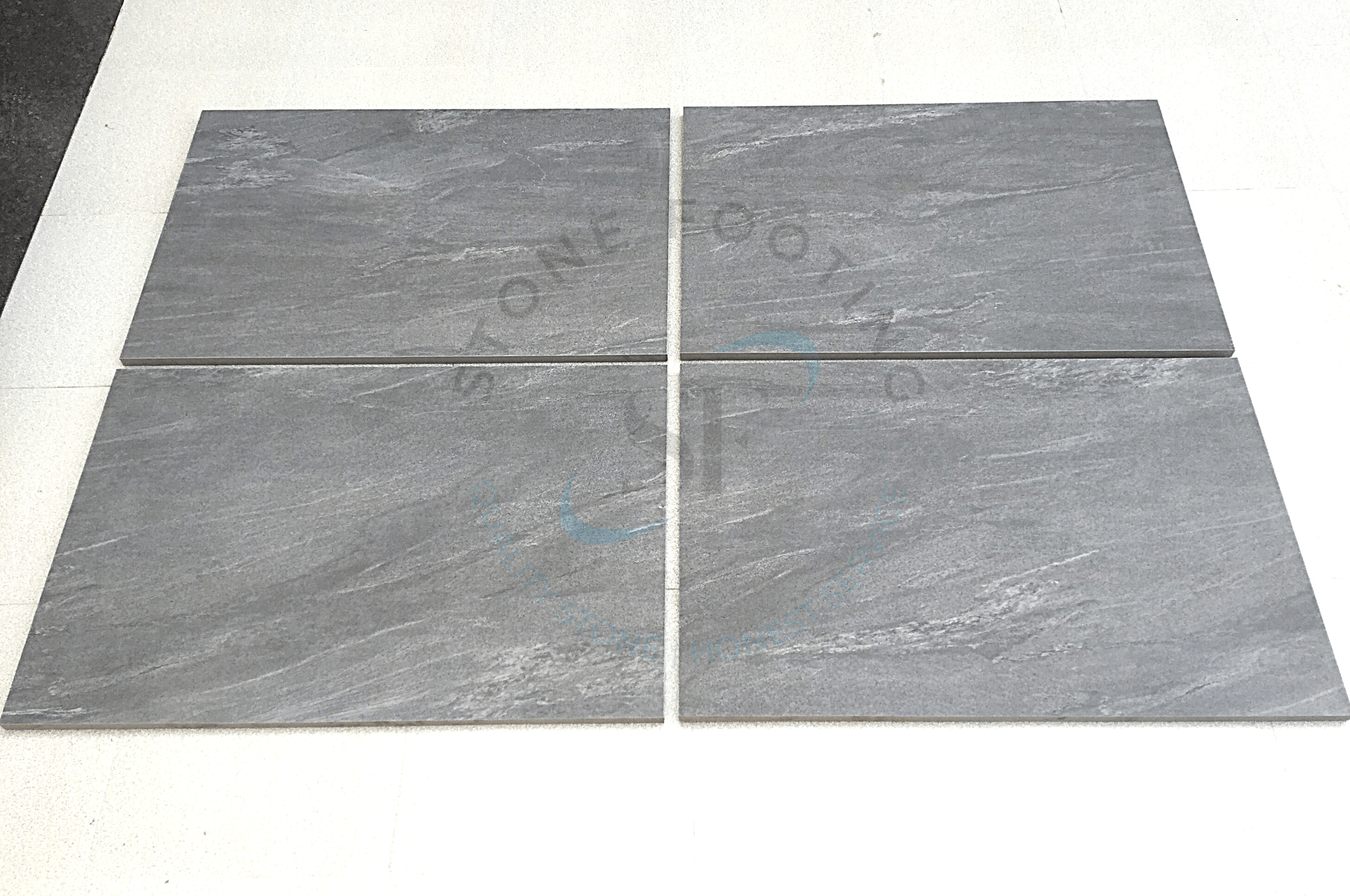

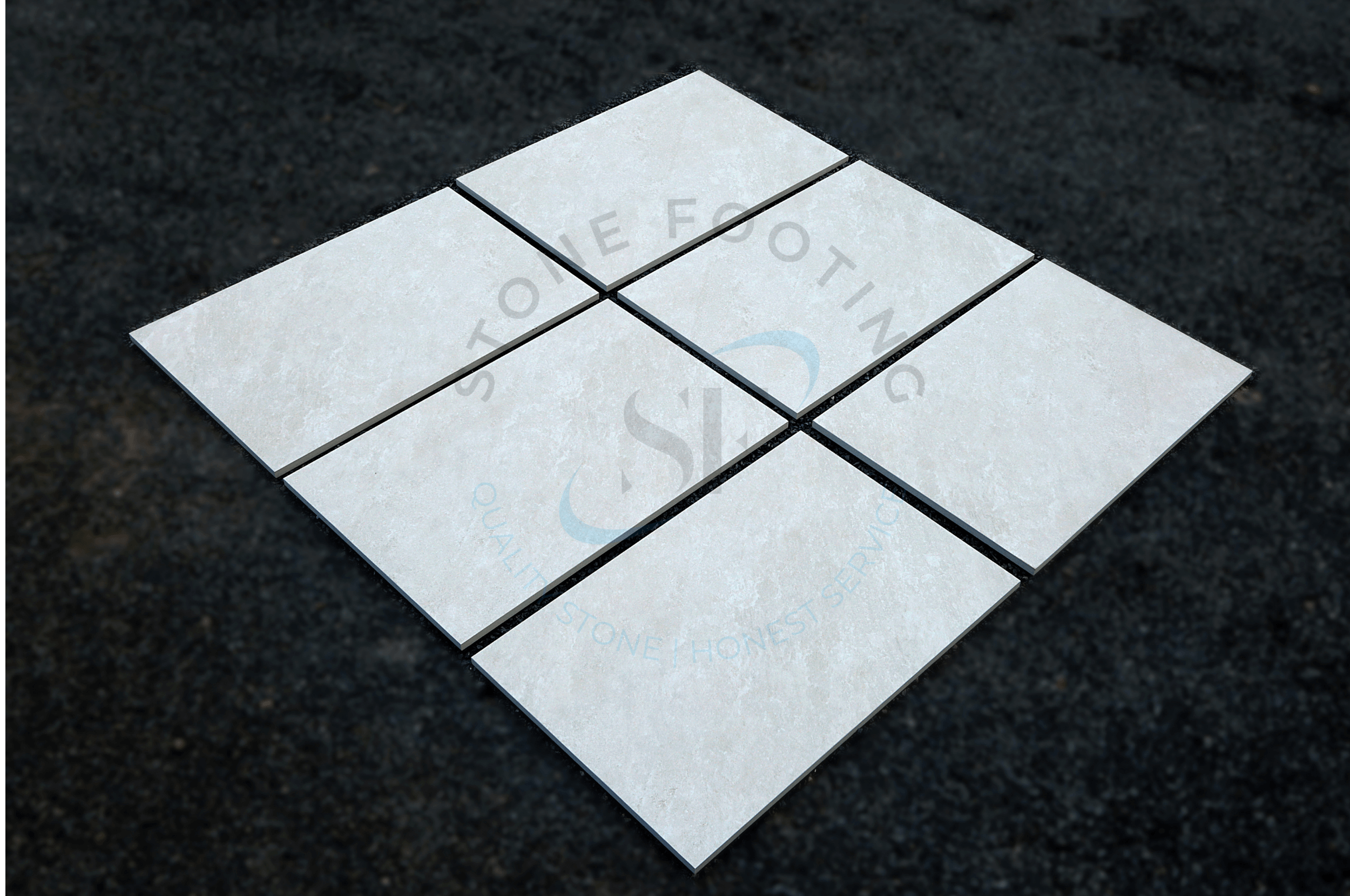

Therefore, if you’re seeking for high-quality natural stone for residential or commercial applications, look no further. Connect with Stone Footing, a natural stone distributor recognised for providing high-quality natural stones.

Frequently Asked Questions

What exactly is mica in granite?

Mica imparts a brilliant, glittering, three-dimensional appearance to granite. Mica is commonly found in the form of flakes and is located in granites such as Delicattus Cream. Because of its fragility, it can cause significant pitting and peel despite its beauty.

What is the most compressible material?

Compressive strengths in concrete and ceramics are often substantially higher than tensile values. Glass fiber epoxy matrix composites, for example, have higher tensile strengths than compressive values. Metals are challenging to test for tension vs. compression failure.

What are the five physical characteristics of stone?

Color, hardness, luster, crystal formations, density, and breakage are characteristics that geologists use to identify minerals in rocks.